Duct Application

Why does my duct sensor with thermowell pocket have accuracy issues?

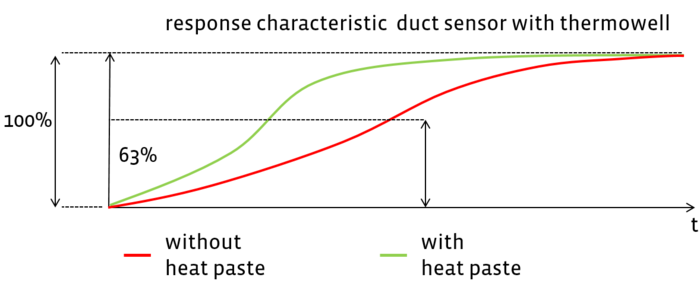

Duct sensors with thermowell pockets react slowly to temperature changes of the medium. This behavior is natural and reasoned by physics. This slow behavior often declares the faced deviation.

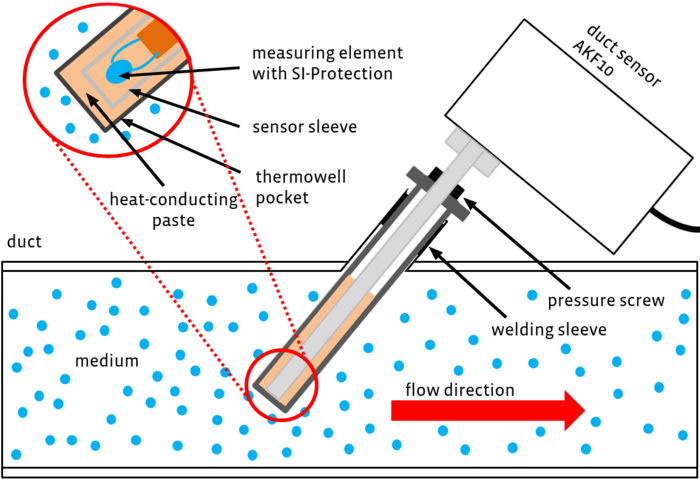

The response time of the whole application can be improved by the use of heat paste. Before mounting the duct sensor, the thermowell pocket should be filled with thermal heat paste at the tip (see below). The heat paste has a better thermal conductivity than air.

Therefore a temperature change of the medium is more responsive and the response time of the installation can be improved significantly.

Which gases can VOC sensors detect?

VOC stands for Volatile Organic Compounds.

These are organic gas combinations that evaporate easily. Examples are:

-alcohols

-carbons

-organic acids

-cigarette smoke

-perfumes

-and so on

An exact list of all VOCs or a binding definition does not exist in literature.

VOC sensors do not detect a specific type of gas. They detect the sum of VOC in the ambient air. VOC sensors from Thermokon produce a relative signal from 0..100% to show the VOC concentration.

How does a VOC sensor get recalibrated?

All Thermokon VOC sensors have an automatic recalibration feature. For measurements, the sensor uses a metal oxide surface, which ages over time. It’s the same procedure as a catalytic converter in a car. Due to this unavoidable wear-off, a recalibration becomes necessary.

In order to recalibrate itself, the sensor stores the lowest VOC measurement value daily. This value is used as a new reference value for following measurements. The sensor produces a relative signal from 0-100%, which is set into direct relation with this new reference value.

For purposes of receiving meaningful measurement values, it is recommended to bring the sensor to fresh air (nearly VOC free) once every 72 hours. Otherwise the measurement value can drift away slowly.

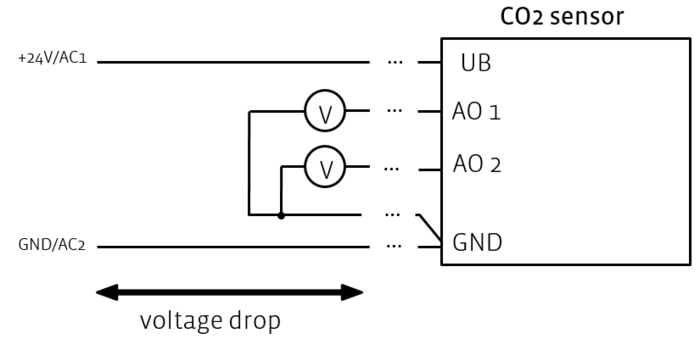

What's to consider when connecting a CO2 Sensor?

CO2 concentration is measured by an optical sensor element. Due to this measurement, CO2 sensors have a temporarily high current consumption.

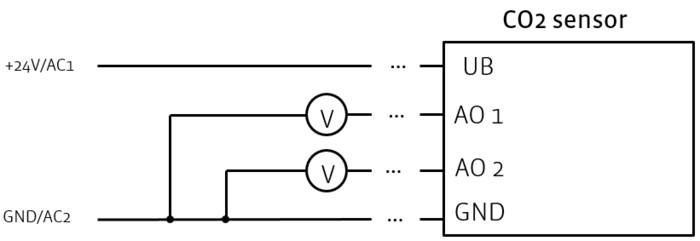

Following problems can occur with the type of connection shown above and a long connection line:

Problem:

The voltage drop across the UB line is so high, that the CO2 sensor is running just within tolerances.

If the CO2 sensor performs a new measurement, the power supply collapses temporarily due to the high current consumption. This voltage drop has a significant influence on the analogue outputs. They show a wrong value temporarily. The voltage drop level depends on the length, the cross section and the operation temperature among others.

Solution:

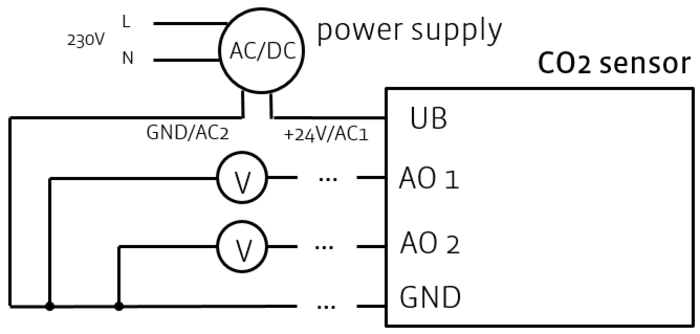

Ensure that the power supply remains within the tolerances. The specified tolerances can be found in the datasheet of the device.

If possible, shorten or change the connection cables (wires). If necessary, install an additional power supply, e.g. Thermokon power supply. (Article number: 645737)

Problem:

If the analogue outputs of the CO2 sensor are connected as seen above (just one GND wire) a deviation will occur. This is due to the unavoidable voltage drop along the GND line. The value of his deviation also depends on the wire length, the wire cross-section and the operating temperature.

Solution:

If a long GND wire is unavoidable, connect the devices as shown below. This connection minimizes the wire cross-section’s influence on the analogue output.

How does a CO2 sensor gets calibrated?

The infrared light source of a CO2 sensor naturally ages over time. That’s why there is a drift that has to be corrected. In order to do so, the CO2 Sensors have an on-board automatic recalibration mechanism.

The type of recalibration is distinguished as follows:

1. Reference measurement – Dual Channel or Dual Wavelength (Thermokon Sensor since 2015)

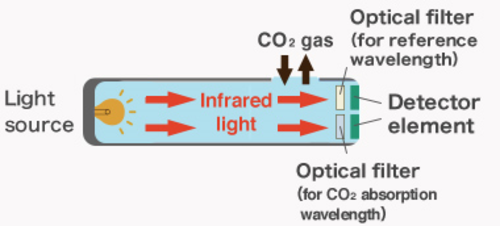

CO2 sensors detect the gas with the help of infrared beams. A specific wavelength of IR radiation is absorbed by the CO2 molecules. This absorption is detected by the detection element and the CO2 level is calculated accordingly.

Dual Wavelength

This technology uses two different optical filters and analyzers. The first one is adjusted to the wavelength, which is absorbed by the CO2 molecules. The second one to a reference wavelength. Due to this reference channel, the actual radiation of the infrared light source is known. So the natural drift can be compensated for by recalibrating it to the reference.

Dual Channel

An additional reference channel performs a measurement just once a day. Thus, the used infrared light source ages slower than the actual measurement channel. The value of the reference measurement is used to compensate the drift.

2. Software algorithms - ABC logic (Thermokon Sensor until 2015)

“ABC-Logic” stands for Automatic Background Calibration. This algorithm stores the lowest measurement value of the last 24 hours. This value is used as a new reference value for all upcoming measurements.

If the sensor gets exposed to fresh ambient air (about 400ppm) at least once a day, the reference value remains at a natural CO2 level and hence is not shifted. If this is not the case, the reference value will be set to the lowest measurement value of the last 24 hours. The ambient air now represents the reference value and is interpreted as being “good” air quality. So the sensor shows wrong measurement values.

In a lot of 24/7 occupancy applications, ambient air measurements once a day are not possible and hence give wrong reference values:

- forced ventilation animal stables

- agrictulture farms

- hospitals

- casinos

- and so on

For these kind of applications, CO2 sensors with the “Dual Channel” calibration i.e. Dual Wavelength suit better.

Since 2015, Thermokon uses CO2 sensors with Dual Channel or Dual Wavelength calibration, as they can be utilized properly in much more applications than ABC-Logic.

Dual Channel CO2 sensors have a more reliable and automatic recalibration for their entire lifetime. In contrast to CO2 sensors with ABC logic, they can also be used in almost every 24/7 application.