General Questions

Why does my device not react after connecting it to an AC power supply?

Ensure the correct connection of neutral conductor and phase. Both must not be interchanged on the whole line. Otherwise, the devices can be destroyed.

The analogue outputs of the devices generate their voltage signal against GND (ground). If there are different ground potentials between the devices, a short-circuit will occur at the PLC (or similar). The devices can be destroyed or have malfunctions.

If there is a common BUS line, a different ground potential will also cause a damage to the device.

When has my device been produced?

Why does my brightness sensor on the table shows other values than the brightness sensor in the ceiling?

The comparison of these two values naturally leads to a difference. However this is caused by the measurement setup and not by the used products.

The luxmeter on the table has its measurement element oriented to the ceiling. Usually that’s the direction of the illumination and the windows (light sources). Whereas the measurement port of the ceiling sensor is oriented to the ground. Therefore the ceiling sensor primarily measures the indirect light reflections of the surface below.

So the measurement value of the ceiling sensor will be lower than the luxmeter's. Between both values exists a constant difference factor. Via this difference factor the illumination at the table can be calculated out of the ceilling sensor's value.

Therefore a reference measurement must be performed once to determine this difference factor.

Why is there a deviation (unreasonable temperature measurement) with my passive temperature sensor?

Passive temperature sensors do not provide a voltage or current output. They change the resistance of the measuring element depending on the ambient (measured) temperature (e.g. PT1000, Ni1000).

This resistance value is transmitted to the controller (DDC, PLC, etc.) by wires and gets interpreted from it.

The resistance value does not only consist of the measuring element’s value. The line resistance and the contact resistance of terminal units are also part of the received signal (resistance) and end up in a slight deviation from the actual resistance of the (measured) temperature.

The wire resistance depends on the used wire type, the wire length, the conductor cross-section and the installation type. Based on these external factors, it may have a significant influence on the transmitted resistance value and may cause a significant deviation on the measured temperature.

Why the SAB05/SAB+ can't be mounted on a valve?

For mounting an SAB acutator on a valve, the drive spindle of the actuator has to be retracted completely.

If this is not the case, please proceed as follows:

SAB05

Open the case cover, remove the batteries wait 10 seconds and reinsert them.

The SAB05 drives into mouting position (drive spindle completely retracted) and can now be mounted on a valve. When successful, it is ready for normal operation again.

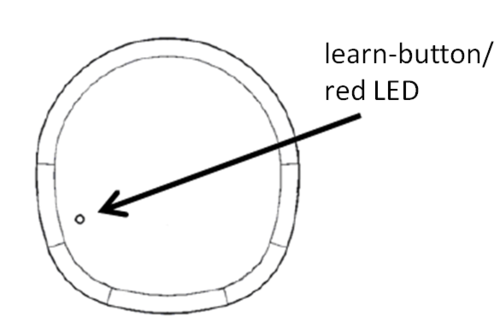

SAB+

Press the learn button on the back of the device for about 5 seconds.

The SAB+ drives into mounting position. The drive spindle is retracted completely and the radio communication is switched off.

After the SAB+ has been mounted on the valve, press the learn button again for about 1 second. Now the SAB+ is ready for normal operation again.

How to prevent theft and vandalism of SAB actuators?

Unfortunately, the theft of or vandalism at SAB actuators occurs. To avoid this, the following measures can be taken:

SAB05

Battery protection: The battery protection SAB05 (item no. 595612) prevents theft of batteries.

The battery compartment can be locked by a special screw requiring a tool.

SAB05 and SAB+

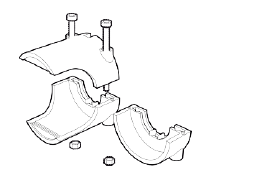

The saftey lock dismounting protection SAB (item no. 706148) prevents the tooless disassembley of an SAB actuator from a valve.

This protection covers the securing nut of the SAB actuator.

Why does the LRWapp/NOVOSapp/USEapp not establish a connection to the Bluetooth dongle?

If it is not possible to establish a connection via the USB Bluetooth dongle, please proceed as follows:

- Reinstall the app

- Restart your smartphone or tablet

- Reconnect the USB Bluetooth dongle with the device

The following operating systems are supported:

- Android 5.0 or higher with Bluetooth Low Energy interface

- iOS 9.0 or higher with Bluetooth Low Energy interface

Furthermore ensure, that your device has full access rights to the Bluetooth interface. Current Android devices also need access to the location services.

Are the analog outputs of a USE BUS device active regardless if BUS is connected or not?

The analogue outputs of a USE BUS device remain active whatsoever.

The measurement values are transmitted via BUS in additon (once connected).

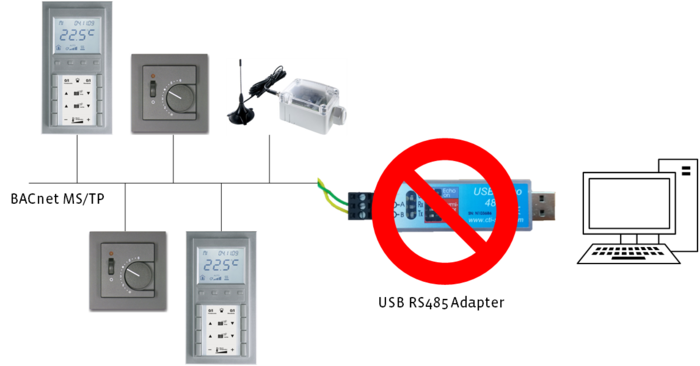

How to connect a BACnet MS/TP network with a PC?

An existing BACnet MS/TP network has to be connected to a PC in order to configure the included devices.

BACnet MS/TP technology interacts with strictly timely coordinated actions within the reach of 1ms. The BACnet MS/TP networks are based on the serial interaface standard RS485. The communication between these RS485 MS/TP network and the serial interface of a PC can cause undetermined time delays. Therefore a reliable communication can't be guaranteed. This issue occurs with windows operating systems especially and is caused by the technical implematation of the serial interface within the operating system itself. Therefore it can't be affected.

The configuration of BACnet MS/TP networks can be done with routers also. These routers connect the MS/TP network with the Ethernet/IP interface of the PC. So possible timming problems of the serial interface are avoided.

Now, a connection to the BACnet MS/TP network can be established by a suitable software like BACeye or others. Oftentimes these Ethernet/IP ⇔ MS/TP router are part of a BACnet controller. They are also available seperately (e.g. MBS UBR-01 | Mk II BACnet).

Note:

Some software tools offer the possibilty to connect the RS485 BACnet MS/TP with the PC directly by the serial interface. Nevertheless Thermokon recommends the solution with MS/TP ⇔ Ethernet/IP. This solution works more reilable and can guarantee a proper communication with the BACnet devices.

What is the difference between a motion sensor and an occupancy detector?

From building automation’s viewpoint the terms motion and occupancy stands for the same issue. Both cases want to indicate if a person is within the detection zone or not.

If the physical measurement method is the same, the different product names motion sensor and occupancy detector just shows different perspectives one the same product. Both names are used synonymously and can’t be distinguished.

Solely the technical characteristics of the product are responsible for the quality of motion or occupancy detection.

PIR motion sensors need a minimum of movement for a reliable function. If there is absolutely no movement the sensor can’t detect motion even if the name “occupancy detector” allows this fallacy.

Further information concernig this matter can be found at the whitepaper Motion and Occupancy detection in buildings.

Why does the motion sensor not detect movement?

Infrared motion sensors need a minimum of movement for a reliable function. Furthermore the motion sensor type, the detection range and the right placement are important.

The whitepaper Motion and occupancy detection in buildings deals with these points in detail.

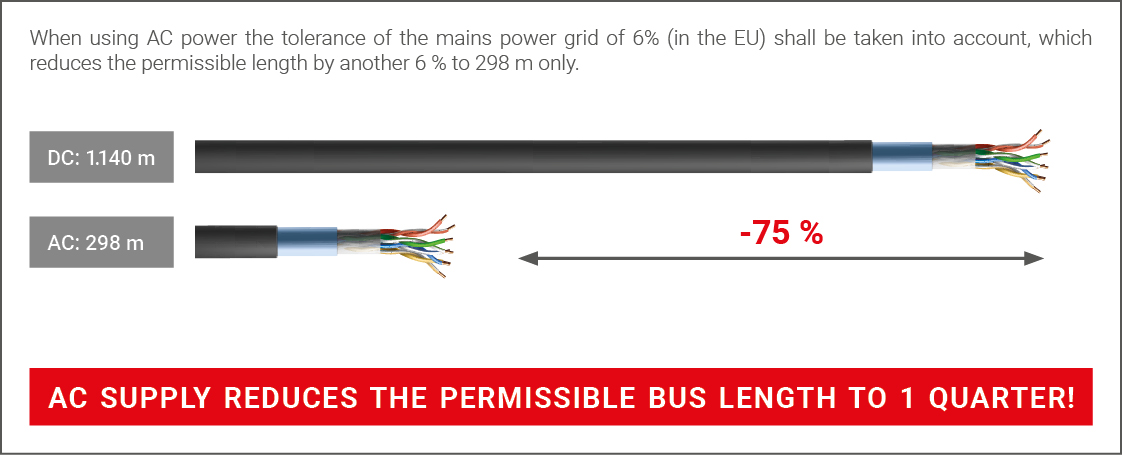

Should I use DC or AC power for bus units?

NOVOS Room operating panels with Modbus or BACnet communication are specified for AC or DC power. Independently of the AC/DC selection, their internal power management generates the controlled DC voltage that supplies display, sensors, etc.

Of course, when conecting multiple devices to the bus the total current consumption will be the sum of all devices. The voltage shall never drop below the minimum value (15V DC / 19V AC) at any device of the bus due to the copper resistance.

Case 1: 24 V AC or DC supply, J-Y(St)Y 2x2xØ0,8, 1x NOVOS Touch

The loop resistance of the frequently used bus cable J-Y(St)Y 2x2xØ0,8 is specified to be typ. 75 Ω/km. The minimum voltage of a NOVOS touch is 15 V for DC power, allowing a voltage drop of 24 V - 15 V = 9 V along the cable.

For AC the minimum supply voltage 19 V AC, allowing a voltage drop of 5 V along the cable.

With DC power This calculates a maximum bus length L of: | With AC power This calculates a maximum bus length L of: |

Case 2: 24 V AC or DC supply, J-Y(St)Y 2x2xØ0,8, 8x NOVOS Touch

Eight NOVOS Touch connected to a Modbus line will limit the maximum bus dimension to a value between 40 and 70 meter, depending on the position of the NOVOS along the bus.

With DC supply the permissible bus length will be 255 m, provided the NOVOS are evenly distributed along the bus.

For longer bus lines either cable with increased wire gauge of the power wires must be used (i.e. UNITRONIC® BUS PB FD P COMBI 1x2xØ0.64 + 3x1.0 mm² or UNITRONIC BUS COMBI EIB 2x2xØ0,8+3x1,5 mm²), or / and the supply power can be fed into the bus cable from both ends (Ring topology for the power supply).

In case the copper resistance is too high resulting in a too high voltage drop all NOVOS with insufficient supply voltage will try to start-up multiple times: NOVOS starts showing the start screen and beeps, but turns black and restarts after a few seconds as soon as the internal sensors start drawing current, causing the voltage to drop below the minimum voltage.

And NOVOS restarts with the same sequence.

This does not only apply to NOVOS or room operating panels, but to USE sensors as well. It may look differently as USE sensors not always have a display and never a buzzer, but the principle is exactly the same.

Conclusion:

A 75% reduction of the permissible dimension of the bus is significant and may be a too high price compared with cost saving of using a more simple AC power supply.

In addition the electricity cost will be double for AC compared with DC power (2,5 W vs. 5 VA) and that extra power causes double the self heating of the device because the extra power will be dissipated in the device’s power management. For sure with AC power the offset setting will need to be adjusted on site for each device during the commissioning process.

Finally AC power inherently bears the risk of destroying the RS485 transceiver in case the polarity of the AC supply is not observed. Due to the half-wave rectification the polarity does matter and must be observed.